What Are Product Costs?

What Are Product Costs?

Definition: Product cost is a term used to denote the total costs or expenses necessary to produce a good. The costs, in this case, can be direct labor costs, raw material costs as well as factory overhead costs. These costs are essential if a factory or a manufacturer is to turn raw materials into finished goods for sale. The costs incurred in this case feature in the balance sheet rather than the income statement.

Likewise, product cost can also be the cost of labor incurred to deliver a given service to a customer. In this case, it might include employee benefits, compensation as well as bonuses. Taxes charged’ by a government or local authority on the final product, service, or raw material also account for total product costs.

Product Cost Components

Product costs has three main components: Direct Material, Direct Labor and Manufacturing overhead

Direct Material

Direct material, in this case, is the costs incurred in the purchase of raw materials used in the creation of the final products. For instance, a wheat flour, producing a company would have to pay a farmer for wheat used in generating flour. Similarly, a company engaged in the production of toys would have to incur direct material costs in the form of plastic costs.

Direct Labor

Direct labor, however, is the total labor costs in the form of wages, benefits as well as insurance incurred in the production process. A large manufacturing company would have to hire people to oversee the entire production process. The personnel would, in this case, earn wages among other benefits that are charged as direct labor in product costs calculation.

Manufacturing Overhead

Manufacturing overhead costs denote direct factory related costs incurred during the production of a good. Such costs include machinery costs as well as costs for operating the machines. Overhead costs may also include indirect costs not traceable to the final product. Such costs may include expenses for oil, tape, or cleaning supplies. Indirect labor costs in the form of security guards and quality assurance workers can also ramp up manufactured overhead costs.

In a bid to eliminate overhead costs, some companies modify product costs when making short-term products and pricing decisions.

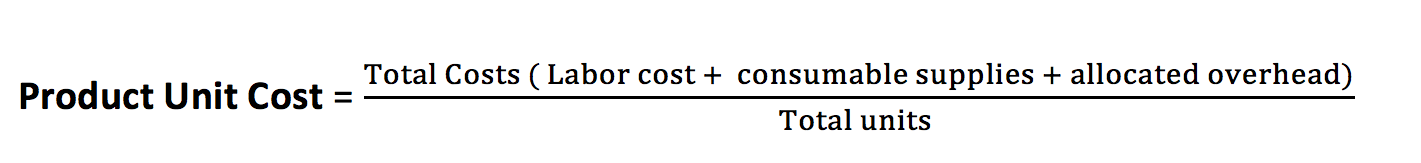

Product Cost Formula Calculation

The cost of a product on a unit basis is derived by compiling all the costs incurred in producing all the units then dividing by the total units produced.

In case a product has not yet been sold, then the product cost would appear as an inventory asset. It is only charged as the cost of goods sold on the income statement when the product is sold and some revenues generated.

In this case, the product cost appears on the income statement as an expense. Product costs also appear in financial statements as they are used in the determination of other financial metrics such as net income and loss.

Product Cost Example

Company XYZ produced 500 beds and incurred the following costs: $10,000 on wood, $200 on nails $2000 on labor, $200 on factory rent, and utilities. The total product costs would in this case be

Product Cost= $10,000 + $200 + $2000 + $200 = $12,400

The per-unit product costs would be $ 12,400/ 500 = $24.8

What this means is that company XYZ will have to sell each bed for more than $24.8 to be able to generate a substantial profit.

Summary

Product costs are simply costs incurred in manufacturing products. The costs, in this case, comprise of raw material costs, labor costs as well a manufacturing overhead costs.

Product costs appear on the balance sheet as inventory. The costs only appear on the income statement when the goods are sold and some revenue generated.